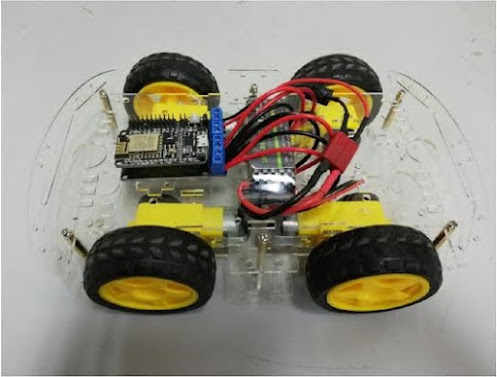

Wi-Fi Controlled Robot Car Using Nodemcu and Blynk

We can control the robot car over the internet for infinite range.

L298 Motor Driver Module 🛒

L298 Motor Driver Module 🛒Software Used:

Getting to Know Your L298N Dual H-Bridge Motor Controller Module .An H-Bridge

- Specifications:

- Double H bridge Driver Chip: L298N

- Logical voltage: 5 V

- Drive voltage: 5V-35V

- Logical current: 0-36mA

- Drive current: 2 A (MAX single bridge)

- Max power: 25W

- Note: Built-in 5v power supply, when the driving voltage is 7v-35v. But i recommend you not to power up your microcontroller with on-board 5v power supply.

1: connect the bo motor to the motor driver as shown

2: connect the motor driver to nodemcu as given below:

- GPIO2(D4)- IN3

- GPIO15(D8)-IN1

- GPIO0(D3)-IN4

- GPIO13(D7)-IN2

- GPIO14(D5)-Enb-A

- GPIO12(D6)-Enb-B

3:Supply Connections :

- +12v - Positive terminal of the battery to be connected.

- GND - Ground terminal of the battery to be connected.

- +5v - +5v input (unnecessary if your power source is less than +7v to +9v, if the power source is greater than +9v to +35v then it can act as a 5v out)

- 4:Input Connections :

- (Motor A) ENA - Enables PWM signal for Motor A

- IN1 -Enable Motor A

- IN2 - Enable Motor A

- (Motor B) ENB - Enables PWM signal for Motor B

- IN3: Enable Motor B

- IN4: Enable Motor B

Note : Make sure you have all of your grounds connected together. (NodeMCU, Power Source, and Motor Driver)The PWM Pins are unnecessary if

- Download the Blynk app from the google play store

- Sign in with a valid E-mail address

- Create a new project

- Give Project a name and choose NodeMCU as the device from the list

- Then choose WIFI as the connection type and press create

- An Auth Token will we generated an sent to the Email address which you signed in

- Copy and save the Auth Token somewhere save and will we used in upcoming steps

- Now click "+" to add widgets, then add a Joystick and Slider .now the Joystick is displayed on the dashboard

- Then click on the Joystick widgets from the dashboard to edit the Joystick settings

- select the virtual pin v1 because

I even have written the code for v1 and slide the button from split to merge - set

the worth range from 0-1023 because it helps in easy control of robot for larger values

- now select the slider , select the virtual pin v2,and set values from 0 - 1023.

- Click on the Icon to open the Arduino window

- Open the File and click on the Preferences

- Adding ESP8266 Board Manager

- In the Additional Boards Manager enter below URL. http://arduino.esp8266.com/stable/package_esp8266... As highlighted in the figure and enter OK.

- Selecting Board

Now open the tools

- ESP8266 Board Package

The Boards Manager window opens, scroll the window page to bottom till you see the module with the name ESP8266. Once we

- Selecting ESP8266 Arduino Board

To run the esp8266 with Arduino

- Connecting ESP8266 to the PC

Now Let’s connect the ESP8266 module to your computer through USB cable as shown

STEP 3: Programming NodeMCU

#include <Esp8266Wifi.h>

#include<BlynkSimpleEsp82666.h>

/* define L298N or L293D motor control pins */

int leftMotorForward = 2; /* GPIO2(D4) -> IN3 */

int rightMotorForward = 15; /* GPIO15(D8) -> IN1 */

int leftMotorBackward = 0; /* GPIO0(D3) -> IN4 */

int rightMotorBackward = 13; /* GPIO13(D7) -> IN2 */

int z;

/* define L298N or L293D enable pins */

int rightMotorENB = 14; /* GPIO14(D5) -> Motor-A Enable */

int leftMotorENB = 12; /* GPIO12(D6) -> Motor-B Enable *

/ You should get Auth Token in the Blynk App. // Go to the Project Settings (nut icon).

// Use your own WiFi settings

char auth[] = "**********";

char ssid[] = "type your network name here ";

char pass[] = "type your network password here";

// neutral zone settings for x and y

// joystick must move outside these boundary numbers to activate the motors

// makes it a little easier to control the wifi car

int minRange = 312;

int maxRange = 712;

// analog speeds from 0 (lowest) - 1023 (highest)

// 3 speeds used -- 0 (noSpeed), 350 (minSpeed), 850 (maxSpeed).

// use whatever speeds you want...too fast made it a pain in the ass to control

int minSpeed = 450;

int maxSpeed = 1023;

int noSpeed = 0;

void moveControl(int x, int y) {

// movement logic // move forward

// y je vetsi jak maxrange a současně x je vetsi jak minRange a současne mensi jak max range

if(y >= maxRange && x >= minRange && x <= maxRange) {

analogWrite(leftMotorENB,z);

analogWrite(rightMotorENB,z);

digitalWrite(leftMotorForward,HIGH);

digitalWrite(rightMotorForward,HIGH);

digitalWrite(leftMotorBackward,LOW);

digitalWrite(rightMotorBackward,LOW); } //MOVE FORWARD RIGHT

else if(x <= minRange && y >= maxRange ) {

digitalWrite(leftMotorENB,maxSpeed);

digitalWrite(rightMotorENB,minSpeed);

digitalWrite(leftMotorForward,HIGH);

digitalWrite(rightMotorForward,HIGH);

digitalWrite(rightMotorBackward,LOW);

digitalWrite(leftMotorBackward,LOW); } // move right

else if(x >= maxRange && y >= minRange && y<=maxRange)

{ analogWrite(leftMotorENB,z);

analogWrite(rightMotorENB,z);

digitalWrite(leftMotorForward,HIGH);

digitalWrite(rightMotorForward,LOW);

digitalWrite(rightMotorBackward,HIGH);

digitalWrite(leftMotorBackward,LOW);

}

// move forward LEFT

else if(x <= minRange && y >= maxRange ) {

digitalWrite(leftMotorENB,minSpeed);

digitalWrite(rightMotorENB,maxSpeed);

digitalWrite(leftMotorForward,HIGH);

digitalWrite(rightMotorForward,HIGH);

digitalWrite(rightMotorBackward,LOW);

digitalWrite(leftMotorBackward,LOW); }

// moveleft else if(x <= minRange && y >= minRange && y <= maxRange) {

analogWrite(leftMotorENB,z);

analogWrite(rightMotorENB,z);

digitalWrite(leftMotorForward,LOW);

digitalWrite(rightMotorForward,HIGH);

digitalWrite(rightMotorBackward,LOW);

digitalWrite(leftMotorBackward,HIGH); }

// neutral zone

else if(y < maxRange && y > minRange && x < maxRange && x > minRange)

{ digitalWrite(leftMotorENB,LOW);

digitalWrite(rightMotorENB,LOW);

digitalWrite(leftMotorForward,LOW);

digitalWrite(leftMotorBackward,LOW);

digitalWrite(rightMotorForward,LOW);

digitalWrite(rightMotorBackward,LOW); }

// move back

else if(y <= minRange && x >= minRange && x <= maxRange) {

analogWrite(leftMotorENB,z);

analogWrite(rightMotorENB,z);

digitalWrite(leftMotorBackward,HIGH);

digitalWrite(rightMotorBackward,HIGH);

digitalWrite(leftMotorForward,LOW);

digitalWrite(rightMotorForward,LOW); }

// move back and right

else if(y <= minRange && x <= minRange) {

digitalWrite(leftMotorENB,maxSpeed);

digitalWrite(rightMotorENB,minSpeed);

digitalWrite(leftMotorForward,LOW);

digitalWrite(rightMotorForward,LOW);

digitalWrite(rightMotorBackward,HIGH);

digitalWrite(leftMotorBackward,HIGH); }

// move back and left

else if(y <= minRange && x >= maxRange) {

digitalWrite(leftMotorENB,minSpeed);

digitalWrite(rightMotorENB,maxSpeed);

digitalWrite(leftMotorForward,LOW);

digitalWrite(rightMotorForward,LOW);

digitalWrite(rightMotorBackward,HIGH);

digitalWrite(leftMotorBackward,HIGH); } }

void setup() {

// initial settings for motors off and direction forward

pinMode(leftMotorForward, OUTPUT);

pinMode(rightMotorForward, OUTPUT);

pinMode(leftMotorBackward, OUTPUT);

pinMode(rightMotorBackward, OUTPUT);

/* initialize motor enable pins as output */

pinMode(leftMotorENB, OUTPUT);

pinMode(rightMotorENB, OUTPUT);

Blynk.begin(auth, ssid, pass); }

void loop() {

Blynk.run(); }

BLYNK_WRITE(V1)

{ int x = param[0].asInt();

int y = param[1].asInt();

moveControl(x,y); }

BLYNK_WRITE(V2)

{ z = param[0].asInt(); } // code end here

HOPE U WOULD HAVE CREATED THIS PROJECT!!!

Comments

Post a Comment

If you have any doubts ,Please let me know.